Filleting waste contains high levels of phosphorus, but a large fraction

is bound in poorly soluble mineral complexes in fish bones. Salmon have a

limited ability to digest phosphorus from fish bones, and most of this

phosphorus in the feed is therefore excreted in an undigested state into the

environment.

Biotechnology innovation

The food research institute Nofima has long been working to develop

biotechnology solutions that can make the nutrients in fish bones more readily

available for salmon.

Senior researcher Sissel Albrektsen and her colleagues at Nofima have

worked on a project financed by the Norwegian Seafood Research Fund (FHF). They have managed to garner a large fraction of the

phosphorus present in herring filleting waste.

Senior researcher Sissel Albrektsen and her colleagues at Nofima have

worked on a project financed by the Norwegian Seafood Research Fund (FHF). They have managed to garner a large fraction of the

phosphorus present in herring filleting waste.“It’s difficult to obtain the phosphorus present in herring filleting

waste, which has a

lower content of bone than other raw materials that we have experience of

using. But we managed it after careful adaptation of a method we use for other

marine raw materials to process and acid treat filleting waste. Our results

show that herring filleting waste may be a significant source of phosphorus

with this technology,” says Albrektsen.

As much as 90% of the phosphorus in the herring bones can be obtained

using this method. This is compatible with previous experience from other fish

species, and salmon fry and smolt can use this source of phosphorus very

efficiently.

An excellent source for salmon smolt

“We have shown that salmon fry during start-up feeding and salmon smolt

after release to the sea can both take up and use the phosphorus extremely

well,” says Albrektsen. “The results suggest, however, that salmon fry are

slightly more sensitive than salmon smolt with respect to the neutralising

agent that is used as buffer during the production. We need to examine this

more closely, and it will be important in whether commercial production can be

successful.

The phosphorus in fish bone hydrolysate can be absorbed from the

intestines just as other readily soluble phosphorus salts used in salmon feed.

The results for rate of growth, phosphorus digestibility and the amount of

phosphorus from the feed that is stored in the fish all show that this is the

case. Our experiments have also shown that the skeleton develops normally when

the fish obtain sufficient phosphorus from the diet, and this is very important

to avoid deformities in farmed salmon.”

Phosphorus is a limited resource and Albrektsen points out that we will

have to find more efficient ways of using the resources we have.

“We have shown that upgrading bone raw material, which has sometimes been seen as hazardous waste from

the production of fishmeal, has a large potential and may be enormously

beneficial as an ingredient in feed. There are indications that fish bone

hydrolysate has further positive properties, such as an ability to improve the

digestibility of several other nutrients and to give improved growth. We plan

to continue to work on this in order to understand fully the potential of the

new ingredients.”

Commercial use

The method is not yet ready for industrial use, but Nofima is involved

in the Forny project, with the goal of commercialising the new technology.

“We do know that the production process for acid hydrolysis requires

relatively small and simple changes in a company, and the requirements for

increased expertise to handle the new processes and product lines are also

relatively small. The investment required is also reasonable, particularly if

the new production lines are located at existing fish landing or fishmeal

production facilities. The greatest investment is needed during the initial

phase,” concludes Albrektsen.

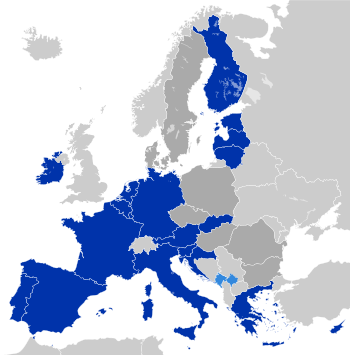

Phosphorus • The EU has identified a reduced availability of phosphorus as one of the greatest challenges facing Europe in the 21st century. • The production of phosphorus is currently controlled by China, the US and Morocco, where the

largest sources are located. • Even though large reserves of phosphates are found in the Earth's soil and under the oceans,

reserves that can be economically exploited are limited - and this means that measures must be taken to eliminate the way phosphorus is currently overused and wasted. • There is a huge global requirement for phosphorus: demand is high, particularly for use in fertilizers (90%), and is growing year by year. • It has been estimated that the volume of marine by-products from the pelagic fish sector, farmed fish and the fishing industry in Norway amounts to approximately 929,000 tonne (2012). Phosphorus from pelagic fish alone corresponds to 60-70% of the amount of phosphorus that is currently added to salmon feed. Sources:

Nofima

SINTEF

The Phosphorous Platform of the EU |

|

| Countries using the Euro de jure Countries and territories using the Euro de facto Countries in the EU not using the Euro (Photo credit: Wikipedia) |

About Nofima

Nofima, the Norwegian Institute of Food, Fisheries and Aquaculture Research, was established in 2008. Nofima is one of the largest institutes in Europe for applied research within the fields of fisheries, aquaculture and food.

The institute has around 380 employees and has an annual turnover of about NOK 530 million.

We carry out internationally recognised research and develop solutions that provide a competitive edge throughout the value chain.

The head office is located in Tromsø, and the research divisions are located in Averøy, Bergen, Sunndalsøra, Stavanger, Tromsø and Ås.

The AquaculturistsThis blog is maintained by The Aquaculturists staff and is supported by the magazine International Aquafeed which is published by Perendale Publishers Ltd.